Process Engineering

5 Months - 120 Hrs

08:00 pm-10:00 pm

3 Alternative days/ week

Eligibility :- Minimum requirement of a Chemical or Petrochemical Engineering degree.

Course Overview

The Process Engineering course is designed to equip students with the skills and knowledge required to excel in the chemical and petrochemical industries. This comprehensive program focuses on the design, analysis, and optimization of industrial processes. With practical exposure to advanced software tools such as Aspen HYSYS, FlareNet, and AFT Fathom, you will learn how to develop efficient and safe process designs that meet industry standards and requirements.

- Module 1: Process Engineering Fundamentals

- Project Theory: Learn the basics of project management and its application in process engineering. Understand how projects are planned, executed, and monitored in industrial environments.

- Process Deliverables: Gain insights into process deliverables, including the generation of key documents required for process design and analysis.

- Module 2: Process Flow Diagrams (PFDs) and Heat & Material Balances (HMBs)

- PFD Development: Understand how to create Process Flow Diagrams, which outline the flow of processes and interactions between different units in a plant.

- Heat & Material Balances: Learn how to develop HMBs, a critical component in process design that ensures the proper balancing of energy and material flows.

- Design Basis: Learn to establish a solid design basis for process engineering projects, setting clear objectives and performance criteria for the design.

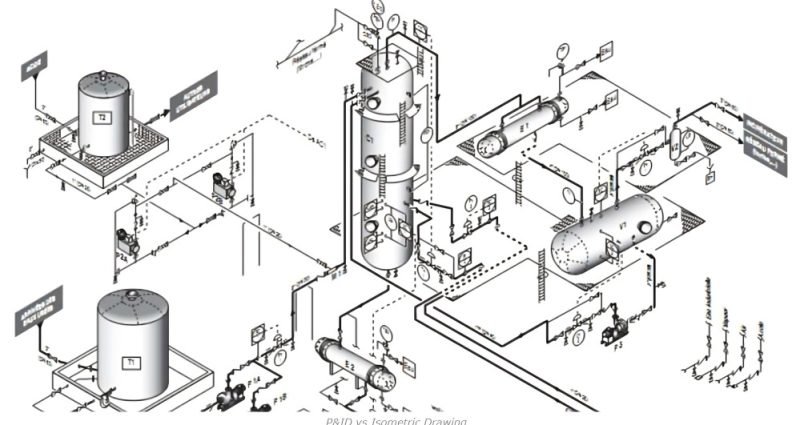

- Module 3: Process Data and Diagrams

- DPDTs (Data Process Diagrams and Tables): Learn to create and interpret DPDTs, which help in capturing detailed process information.

- P&IDs (Piping & Instrumentation Diagrams): Master the creation and interpretation of P&IDs, which are essential for designing and operating industrial processes.

- Line Lists: Understand how to develop line lists, which document important details about piping in process systems, such as size, type, and material.

- Module 4: Basic Engineering Design Data (BEDD) & Process Design Criteria

- Process Design Criteria: Learn to set process design criteria, which define the key design parameters for equipment and systems.

- BEDD Development: Understand how to develop Basic Engineering Design Data, which serves as the foundation for detailed engineering.

- Module 5: Hydraulics and Line Sizing

- Hydraulic Calculations: Learn how to perform hydraulic calculations to ensure proper fluid flow through pipes and equipment.

- Line Sizing: Understand the principles and calculations used to determine the correct sizing of pipelines for safe and efficient operation.

- Module 6: Pump and Vessel Sizing

- Pump Sizing: Gain the knowledge needed to size pumps based on flow rate, pressure, and process requirements.

- Vessel Sizing: Learn how to size vessels used in process systems, such as separators, reactors, and storage tanks, ensuring safety and efficiency.

- Module 7: Tank and Heat Exchanger Design

- Tank Design: Study the design principles for storage tanks, including the selection of materials, size, and safety features.

- Heat Exchanger Design: Learn how to design heat exchangers, crucial for transferring heat between fluids in process systems.

- Module 8: Instrumentation and Pressure Safety Valves (PSV)

- Instrument Datasheets: Understand how to develop datasheets for instruments used in process control and monitoring.

- PSV Sizing: Learn the process of sizing Pressure Safety Valves, critical components that protect systems from overpressure.

- Module 9: Software Training for Process Design

- Aspen HYSYS: Gain hands-on experience using Aspen HYSYS for process simulation and design, a key tool for engineers in the chemical and petrochemical industries.

- FlareNet: Learn to use FlareNet for designing flare systems, ensuring safe and efficient disposal of gases.

- AFT Fathom: Study fluid flow in piping networks using AFT Fathom, a powerful tool for simulating liquid and gas flow in pipes.

- AFT Arrow: Master the use of AFT Arrow for analyzing compressible flow through piping systems, ensuring proper pressure and velocity profiles.

- Module 10: Advanced Topics and Case Studies

- Utility and Chemical Summary: Understand how to develop utility and chemical summaries, detailing the requirements and usage of utilities like water, steam, and chemicals.

- Hazardous Area Classification: Learn about the classification of hazardous areas based on process inputs, and how to design systems that meet safety standards.

- Effluent Summary: Study how to prepare effluent summaries, detailing the safe and environmentally compliant disposal of waste products.

- Module 11: Specialized Process Activities

- Hydraulics and Line Sizing: Perform advanced calculations for line sizing and hydraulic flow to optimize piping systems.

- Flarenet and PSV Design: Learn the integration of FlareNet with PSV sizing to ensure efficient and safe flare systems in process plants.

- Module 12: Process Design Reports and Deliverables

- Adequacy Reports: Develop and review adequacy reports, ensuring that systems meet design specifications and are fit for purpose.

- Study Reports: Learn how to create study reports that assess different design alternatives, providing recommendations for optimal solutions.

- Module 13: Process Control Systems

- Cause & Effect Diagrams: Learn how to create cause-and-effect diagrams to analyze potential failures and their effects on system performance.

- Control Narratives: Understand how to develop control narratives, which detail the logic and operation of process control systems.